IntroductionThe

purpose of this document is to give guidance to approved contractors and suppliers

who are engaged in the fire stopping of service penetrations in fire rated

structures

using the Astro DL COVER. All service holes through floors and compartment walls

must be fire stopped to prevent the passage of fire, smoke and hot gases.

- Prevent the spread of fire, smoke and hot gases through a building

by containing it in the compartment of origin.

- Maintain the integrity of escape routes from a building.

- Reduce loss or damage to property from the effect of fire and smoke.

- Maintain pressure differential between compartments and ventilation

channels.

Downlighers in ceilings are widely used in commercial buildings.

Each ceiling is subject to fire regulations and where applicable the ceiling construction

needs to be fire rated. However, once a hole has been made in the ceiling for

a downlighter, the integrity of the construction and its ability to perform in

a fire can be reduced significantly. To combat this the ASTRO

DL Cover has been developed to cover maximum protection for holes created by the

introduction of a downlighter and to allow for maximum ease of fitting. In

a fire situation the cover expands internally to fill all the available space

with a highly insulating fire resistant char. Thus, the fire is unable to penetrate

the hole and the cover is able to give additional insulation protection to the

ceiling void to reduce the chance of heat build up and ignition of flammable materials

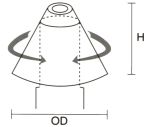

such as accumulated dust and insulation FH DC150 -

150 x 150 - To suit cutout 50 —75 mm FH DC200 - 200 x 200 - To suit

cutout 75-100 mm FH DC250 - 250 x 250 - To suit cutout 100-140mm FH

DC300 - 300 x 170 - To suit cutout 145 -270mm FH DC350 - 350

X 230 - To suit cutout 145-270 mm

| |  |

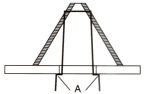

Step One: Grasp legs firmly and roll cover into

a tight cylinder. Ensure wiring loom is through slot before installation.

|  |

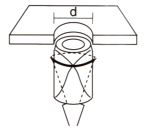

Step Two: Keeping a tight grip on the legs, feed the cover through

the cut out made for the downlighter. |

|

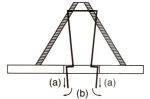

Step Three: Ensure cover has sprung back into its original cone shape. (a) Grasp legs and pull down until L section clears the

underside of the ceiling. (b) Move legs out until vertical part of L section normal.is

flush with the side of the cut out. |  |

Step Four: Release legs so that they grip the underside of the tile.Remove

the excess of both legs. Cut at point A.Once cover is in place, downlighter can

be fitted as normal. |

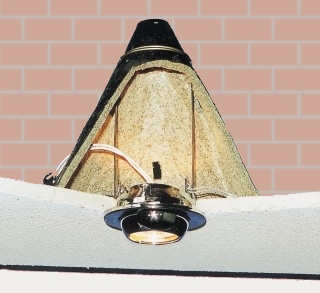

The completed installation.

|

|  | Step One: | Flatten

the cover | |

| Step

Two: | Fold the cover

into quarters by folding it in half once .... |  | .....

and then folding it in half again. |  | Step Three: | Pass

the folded cover through the aperture. |  | Step

Four: | Then

fit the downlighter cover as per the manufactures's instructions - cables may

be pushed through the vent slots in the cover. Check and ensure

that there is a distance of 20mm minimum between the downlighter cover and any

insulation or acoustic filling in the void. | | Remote

gearboxes and transformers must be situated outside of the downlighter cover. |

| The completed

installation.

| Compliance Intumescent

downlighter covers are manufactured in the EU, meeting the highest quality standard

in compliance with ISO EN 9001:2000 . Testing certification

Passed

and certified at BRE to BS EN 1365-2 :200

Test report no. CC 203791A.

Passed

and certified at Chiltern International Fire to BS 476 Part 22 1987.

Test

report no. CHILT/A02166B

Passed and certified at Chiltern International Fire

to BS 476 Part 23 1987.

Test report no. FEA/F00063

Storage

and disposal

Astro DL Covers should be stored indoors. No shelf life is given

as this product will not deteriorate in storeage. |

| |

| As part of our policy of ongoing

improvements, we reserve the right to modify, alter or change product specifications

without giving notice. Product illustrations are representations only. All information

contained in this document is provided for guidance only, and as TLC has no control

over the installation methods of the products, or of the prevailing site conditions,

no warranties expressed or implied are intended to be given as to the actual performance

of the products mentioned or referred to, and no liability whatsoever will be

accepted for any loss, damage or injury arising from the use of the information

given of products mentioned or referred to herein. TOP

OF  PAGE PAGE | |