|

|

|

Click the image

for a larger version in a new window

|

Power Shower

Site Requirements - Electrical

The pump must be permanently connected to the electricity

supply via a double pole isolating switch with a minimum contact

gap of 3mm in both poles. The switch must be readily accessible

but out of reach of a person using a fixed bath or shower,

except for the cord of a pull cord operated switch. The wiring

must be connected to the switch without the use of a plug

or socket outlet. The supply cable selected for installation

must conform to the relevant table in the I.E.E. regulations.

To enhance electrical safety a 30mA RCD (Residual Current

Device) should be installed in all UK electric and pumped

shower circuits. This may be part of the consumer unit or

a separate unit.

This Installation Must Be Earthed

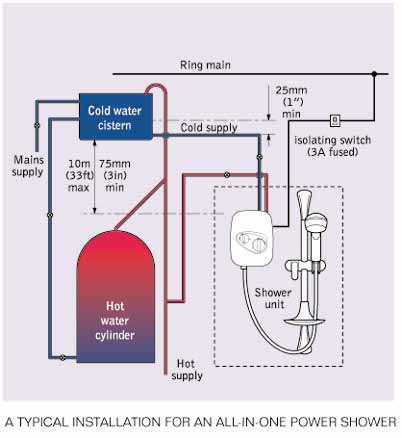

Site Requirements - Water

To ensure correct operation the pump must be connected to

a cistern fed supply of hot and cold water at nominally equal

pressures. The pump must never be connected to the mains cold

water supply. The cold water cistern must always be above

the pump to ensure priming of the unit (see diagrams for details).

The hot water storage cylinder and cold water cistern should

each have a minimum storage capacity of 114 litres in order

to ensure adequate infill rate. If supplying a number of outlets,

it is recommended that the cold water cistern should have

a minimum capacity of 230 litres in order to ensure adequate

infill rate. Both hot and cold water supplies to the pump

must be dedicated and separate from any other outlets or connections.

Water Connections

Inlet Connections:

- 15mm push-in fittings

- Rising, falling and rear entry water supplies

Outlet Connections:

- Threaded 1/2" BSP

- Top, bottom and rear cable entry points

Pump Motor Specifications

Single impeller pump

Rating - 50Hz, 230/240V, 150W, single phase, recommended

duty cycle 15 minutes on, 45 minutes off

Automatic resetting thermal overload cut-out

Flow Rate: up to 14 litres per minute

Pressure: Maximum pressure at maximum flow 1.2 bar equivalent

to a 12.6 head of water

Materials of Construction

Acetal, nylon and ABS

| Dimensions (mm) |

|

|

| Height 268 |

Width 206 |

Depth 138 |

Product Approval

Designed to comply with Water Fitting Bye-Laws Scheme operated

by The Water Research Centre

Power Shower Packs and AS2000T only: thermostatic performance

designed to conform to British Standards

Designed to comply with the latest product electrical safety

standards

Company Approval

Triton is registered by The British Standards Institute and

all Triton products are designed, tested and manufactured

under Quality Management Systems certified to BS EN ISO 9001

: 1994 and Environmental Management Systems approved to ISO

14001.

Guarantee

All in one power showers and power shower pack pumps are

covered by a 12 month guarantee (power shower pack mixer valve

has 3 year guarantee) from the date of purchase. For a small

premium this can be extended to 3 to 5 years (for full details

please see the warranty application form included in every

Triton shower pack).

Installation

Installation should be carried out by competent tradesmen

in accordance with the detailed fitting instructions (supplied

with every unit) and Water Regulations and Bye-Laws. A copy

of the fitting instructions is available on request from the

Customer Service Department if it would help when planning

your installation.

Trade Installer Hotline

Trade installers can phone a dedicated hotline on 024

7632 5491 for immediate technical advice on installation,

and to ensure product suitability for commercial and multiple

installations.

|