|

Author:

John English

Discover how to make a custom router

table insert below... |

A stand-alone

cabinet is perhaps the most desirable arrangement for a router

table. It provides storage space for extra routers, bits,

bases and wrenches, plus it's heavy enough to be stable. Such

a unit can be custom built to suit your own height (it should

be half as tall as you are), and it can be fitted with casters

to make better use of limited shop space.

There

are several portable tables available commercially, but their

biggest drawback is a small tabletop (a real pain when you're

working on a large project). And because they're portable,

they're inherently lightweight, so stability can be an issue.

One ingenious

option I've always found attractive is a table attached to

the underside of an open bench. By mounting it on full-extension,

heavy duty drawer slides, it can be pulled out during use

and pushed out of the way when the job is done.

My

favorite placement option is to build the router table as

an extension of the table saw table. This allows me to use

the saw's expansive top for support, take advantage of an

already installed dust collection system, use the fence system

on the saw as a fence for the router, and even employ the

saw's miter gauge in certain operations. A router table can

easily be added to the DW746 table saw inset boards for the

52" rail system.

Select

the Right Stock for the Top

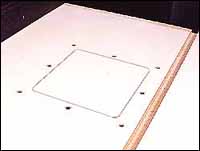

Plastic laminate is an ideal surface

for router tables, and light colours are very desirable

as they make the workpiece more visible. They also allow

you to make pencil marks indicating start and stop positions

for cuts. Shown here is a white laminate top with a new

insert waiting for a router. |

A router

table has to be flat, smooth, slick, stable and the right

colour. Flat and smooth are obvious, but slick? You must choose

a tabletop material that will allow workpieces to slide easily

against both the table and the fence, creating the least possible

amount of friction. If the action is retarded, each pass will

be too slow (which results in burning by the bit), or uneven.

This can even be dangerous, as a novice may try to compensate

by pushing too hard or too quickly.

The top

has to be stable: that is, it must remain flat (without sagging)

for several years of use. This can be a challenge on larger

tables without center support, so make sure it's thick enough.

Your tabletop also should be a light color (preferably white),

so the workpiece is easily visible. Many commercial tables

are a dark grey or black colour, and stock like walnut tends

to visibly merge with this background (especially for old

guys like me whose eyes are already questionable!).

The

ideal tabletop is a medium density fiberboard (MDF) substrate

covered with plastic laminate like Formica™, or a thinner

material such as Melamine™. Make sure you cover both faces,

to equalize tension and avoid warping. And to make it smooth,

sand the top with 400 grit wet/dry paper. The first time you

do this, it's a little unnerving to sand brand new laminate!

After

sanding, use a tack cloth to clean the top. Then make it slick

by rubbing in a coat of clear shoe polish. Buff the shoe polish

for an incredibly smooth, slick surface that won't rub off

on your unfinished wooden workpieces.

Use

Your Saw's Mitre Gauge

Whether

you build a separate, free-standing unit or incorporate a

new table into the table saw, take advantage of the saw's

miter gauge to add versatility to the router. By plowing a

groove in the top (shown at left), you can drop the mitre

gauge into it (right) and make very accurate crooscuts and

end cuts on small stock.

Mounting

the Router

There

are three ways to mount your router in your new table. You

can simply drill three holes and screw the tool's base plate

to the underside of the table. Or you can buy and install

one of several over-the-counter options (shown below, left

photo). But the most satisfying choice is to make your own.

The below instructions are ideal for a smaller router. If

you plan to mount a larger router, you may want to increase

the size of your insert.

Begin

by cutting a 6-1/2" circle in the center of a 12" square piece

of tabletop material. This is easily done with a jigsaw or

scroll saw. Next, cut an 8" square hole in the top of your

table: drill the four corners with a 3/4" Forstner bit, then

jigsaw the straight lines.

Center

the 12" piece of material under the 8" square hole and screw

it in place from underneath the tabletop.

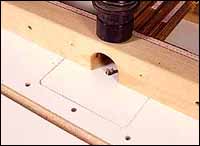

Make

an 8" square insert to fit the square hole. Bevel the edges

at 5 degrees and sand the corners round to fit. The object

here is to make an insert that will simply drop and stay in

place, without any screws or fasteners (below, right).

After

mounting the router to the bottom of this insert (remove the

routers handles to make mounting easier), you should be able

to remove and replace the router efortlessly. This makes bit-changing

a easy: you never have to fumble around under the table.

Depending

on the amount of travel your router has in its base, you may

need to reduce the thickness of the insert. Simply place the

router on the underside of the insert, draw its outline, and

then use the router and a straight bit to remove about half

the thickness of the material (see photo at the top of this

page). This is a freehand operation, as the edges don't have

to be absolutely perfect because it will be hidden from view.

When

the router is secured to the insert, place it in the table

with a straight bit installed. Turn on the router and slowly

plunge the bit through the insert.

Fence

Options

There

are several options for both shop-built and commercial fences.

The most common idea is to make an L-shaped fence that can

be attached to the tabletop with a clamp at either end, such

as the Woodhaven model shown here (right). Another popular

option is to slide the clamps in grooves plowed in the tabletop

(shown at left). A third and very simple fence is one that

is attached at one end with a pin or bolt that acts as a hinge.

The other end is moveable, and is simply secured to the table

with a C-clamp. Unfortunately, this latter style precludes

the use of a mitre gauge slot.

Sometimes

a fence isn't necessary, as when you are routing with a bearing-guided

bit. In this instance, it's a good idea to install a starting

pin in your tabletop. This is usually made of steel or aluminium,

and it's about 1/4"-3/8" in diameter and perhaps 1" long.

It can be fashioned by cutting the head and threads off a

bolt, or it can be purchased through woodshop catalogues.

Drill a 1/2" deep hole in the tabletop about 4" from the bit,

to install the pin.

Dust

Collection

Even

if your router has built-in dust collection, adding a vacuum

port to the fence is a good idea. Lower dust levels provide

a safer, more accurate work environment. Even

if your router has built-in dust collection, adding a vacuum

port to the fence is a good idea. Lower dust levels provide

a safer, more accurate work environment.

Most

shop vacuum and dust collector manufacturers supply ports

that can be attached to a fence. These are generally just

screwed in place. In the event that you can't find a port,

try using a hose-to-hose connector such as the one shown at

right. This connector was designed to connect a large hose

to a smaller one. We simply drilled a hole in the fence that

was exactly the same diameter as the smaller hose. The hole

right above the bit for virtually dust-free routering, and

if the connector is a friction fit it can be removed in an

instant.

One nice

option currently available from woodworking cataloguess is

an ON/OFF switch for a router that simultaneously turns on

the dust collection device. The second outlet (for the collector)

is a slow start affair that prevents circuit breakers from

tripping too soon.

Return to

Top

|