EV Chargepoint Installation – Top 10 Tips

Following the recent Government funded audit into the installation of Domestic Electric Vehicle Chargepoints under the Electric Vehicle Homecharge Scheme, several recommendations were made to enhance safety and compliance.

Some of the recommendations from the report were pertinent to the installation of Electric Vehicle Chargepoints (EVCP).

These are summarised below and installers of EVCPs are encouraged to review this advice as part of their Continuing Professional Development (CPD).

1. Existing Electrical Installation Checks

In the absence of an Electrical Installation Certificate (EIC) for a new build property or full re-wire, a full and thorough periodic inspection and test, in the form of an Electrical Installation Condition Report (EICR), is recommended on the existing electrical installation within the domestic property prior to an EVCP being installed. If this EICR is satisfactory the installation of the EVCP can proceed.

This would entail an inspection and test of all parts of the electrical installation, as well as a load assessment to establish whether a load management system is needed to prevent the installation being overloaded. The inspection and test will determine whether the installation is adequate for the addition of an EVCP. This requires an assessment of the distribution equipment and service head.

Issues found with the distribution equipment and/ or service head should be reported to the electricity supplier and/or DNO and work should not continue on the EVCP installation until the defects have been rectified.

Where there are inadequacies with the DNO/Suppliers equipment the person ordering the work should contact the appropriate authority. The symbol used to record these issues on an EICR is X.

If any C1, C2 or FI codes are recorded, these must be subject to corrective action before the EVCP can be installed.

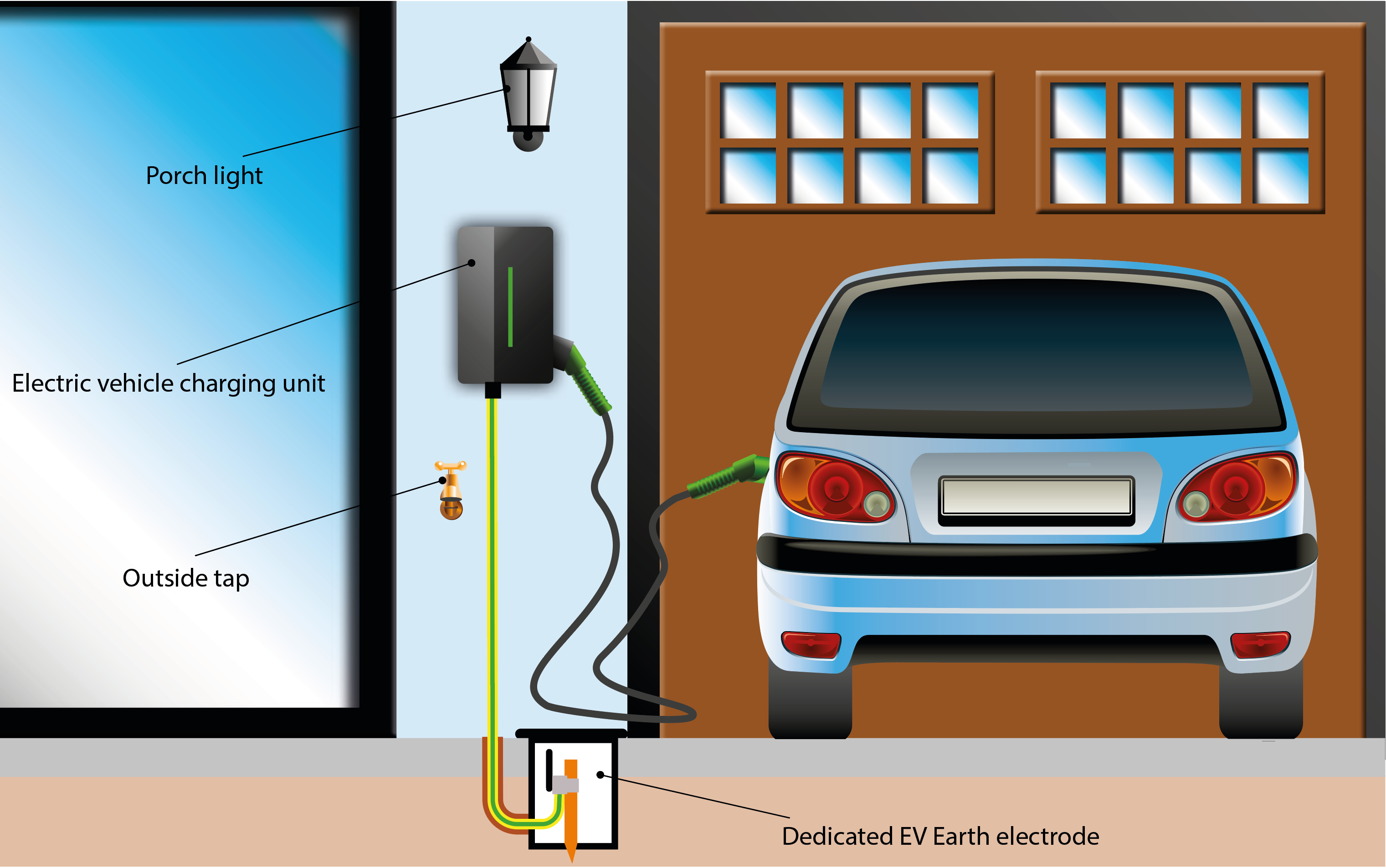

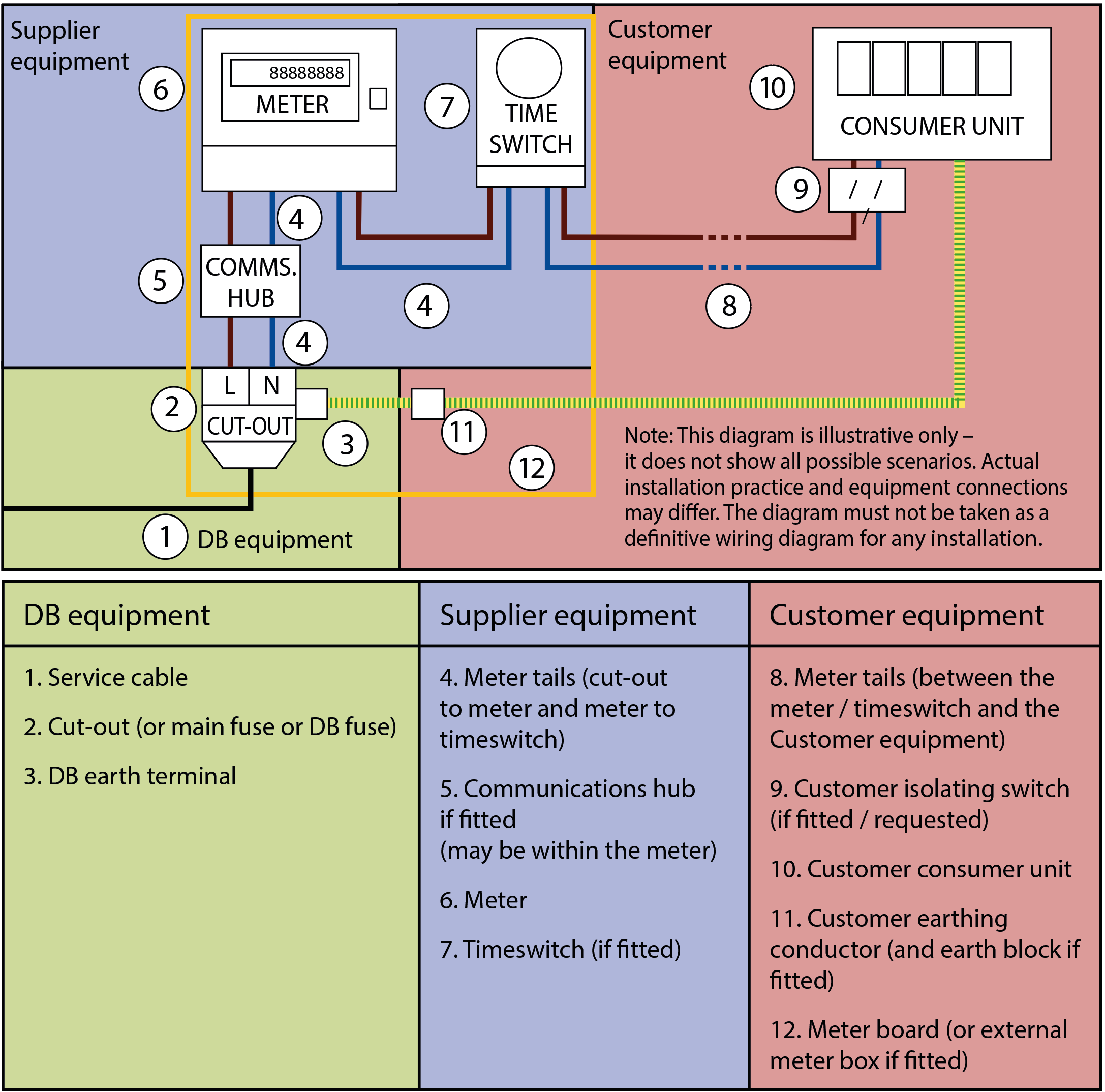

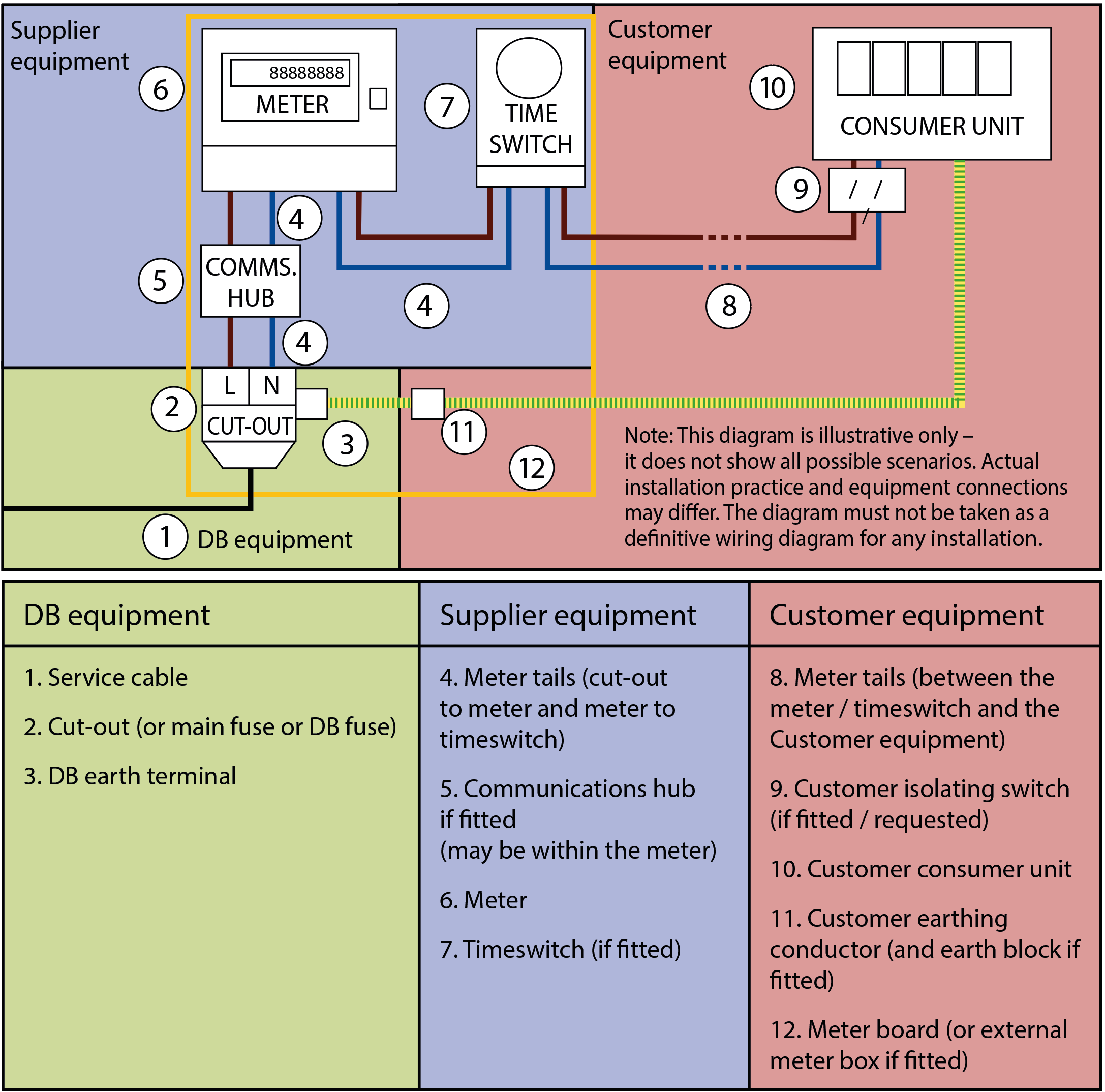

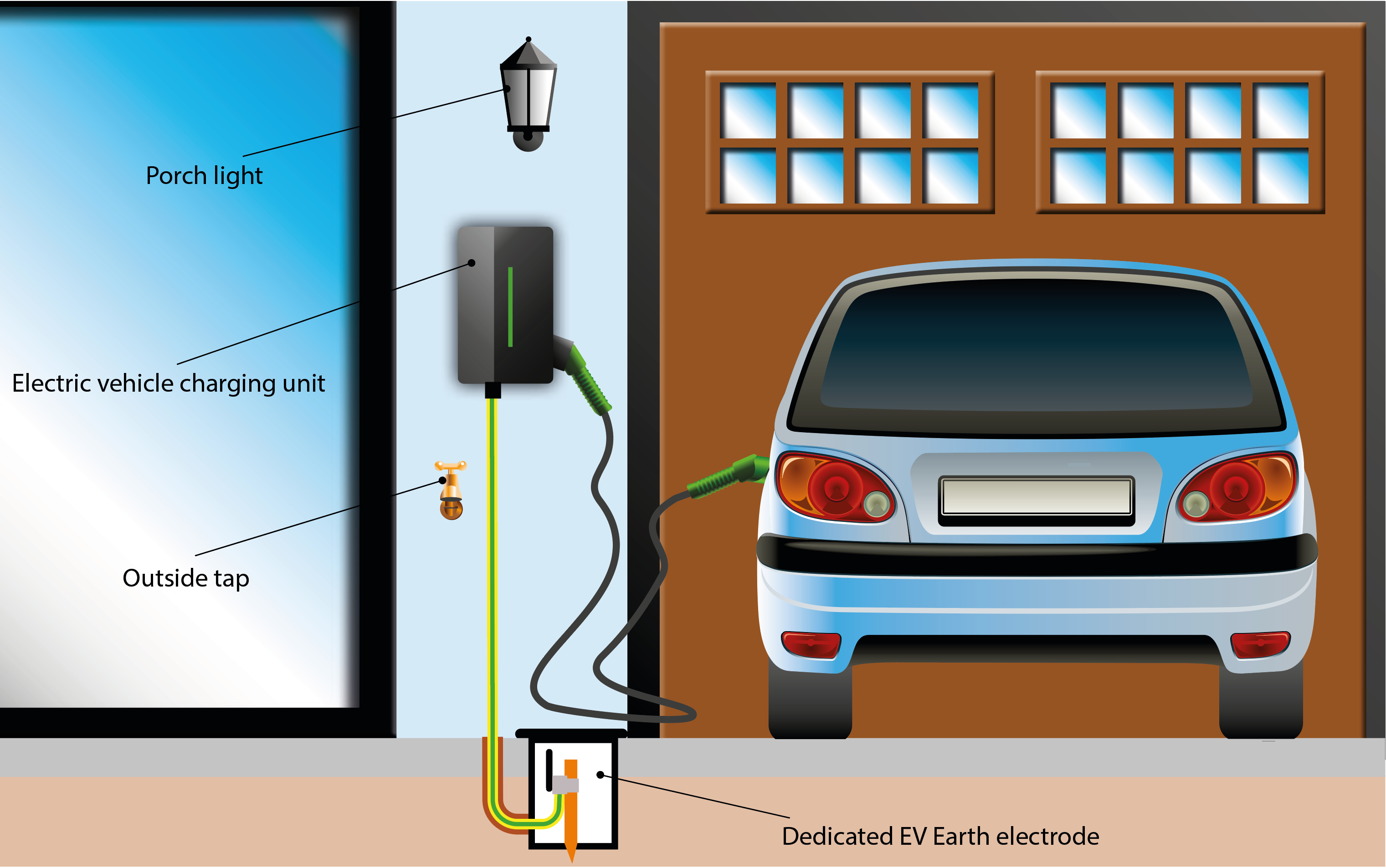

Fig 1. shows a typical domestic setup. The diagram aims to clarify boundaries of responsibility.

2. Supply Earthing

Ensuring correct earthing of EVCPs is one of the key focal points of BS 7671 Section 722 Electric Vehicle Charging Installation. In order to comply with Section 722, the installer must ensure that protection is provided against electric shock.

Options for protecting against electric shock:

-

Use an EVCP that has an inbuilt device that disconnects the chargepoint from the live conductors of the supply and protective earth in accordance with Regulation 543.3.3.101(ii)

-

Convert the chargepoint circuit to a TT earthing system and install one or more earth electrodes

-

Install a Protective Earthed Neutral fault detection device

TN-C-S/TN-S Premises

Requirements on the use of TN-C-S earthing systems prohibit such a connection for outdoor EVCPs.

TN-S earthing systems also have restrictions. Therefore the distributors earthing system must be verified.

TT Premises

The adequacy of the existing TT earthing system must be checked before being used for the EVCP installation.

3. Adequacy of Supply

As EVCPs are high power electrical devices, it is necessary to ensure that the EVCP that will be installed will not overload the maximum supply current for the premises.

To determine when to notify the DNO:

| New Maximum Demand |

Can connect and notify DNO |

Must apply for connection prior to installation |

Install EVCP and notify via ENA form with 28 Days |

Complete ENA form for DNO to assess installation |

Complete ENA form for DNO to check if additional work to be done |

| ≤ 60 Amps |

|

N/A |

|

N/A |

N/A |

| 60-100 Amps |

N/A |

|

N/A |

|

N/A |

| > 100 Amps |

N/A |

|

N/A |

N/A |

|

Assessing Maximum Demand for the installation of EVCPs.

For EVCP installations there is a requirement to assess the maximum demand of an existing installation.

The maximum demand is the connected load including any allowance made for diversity, which is referred to as the maximum anticipated load or the actual load.

The existing maximum demand must be reviewed as the EVCP electrical load cannot take diversity into account.

Example:

To determine the maximum demand of an installation using diversity, the example illustrated below assumes the circuits of a 10-way consumer unit with a main switch rated at 100 A. It has four spare ways and supplies six circuits as follows:

-

One 40 A cooker circuit

-

One 16 A immersion heater

-

Two 32 A ring final circuits

-

Two 6 A lighting circuits

Solution

40 + (0.4 x (32 + 32 + 16 + 6 + 6)) = 76.8 A

Therefore, the 100 A rated main switch is satisfactory for the loading for the existing installation.

Adding the new EVCP circuit to the above worked example

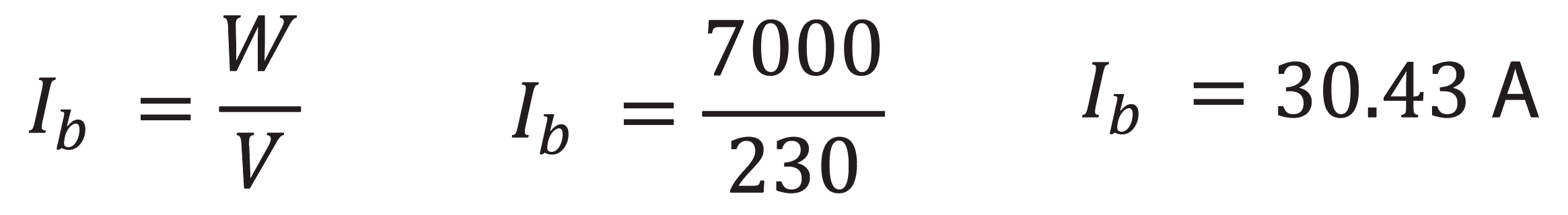

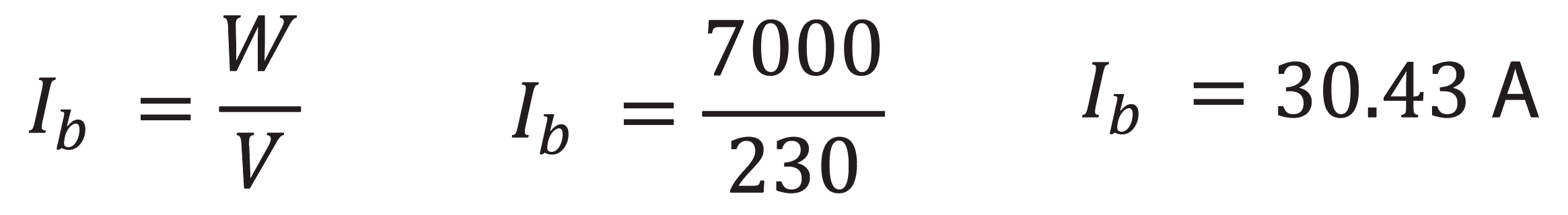

If an EVCP circuit of current rating, say 7 kW, is to be added, the additional current load would be:

The calculation shows there is no allowance for diversity, therefore the EVCP full load is to be used = 30.43 A

There is now an option to reduce the loading by the use of load curtailment which can be used in determining the maximum demand.

The inclusion of the EVCP creates a new maximum demand of 76.8 + 30.4 = 107.2. Therefore the new maximum demand exceeds the current rating of the consumer unit, this arrangement is unacceptable and would require an application to the NO to assess the service intake equipment.

As you can see in the above example, detailed information will be required on the electrical equipment installed within the premises to allow the maximum demand figure to be determined. A completed EVCP connection form will need to be sent to the DNO.

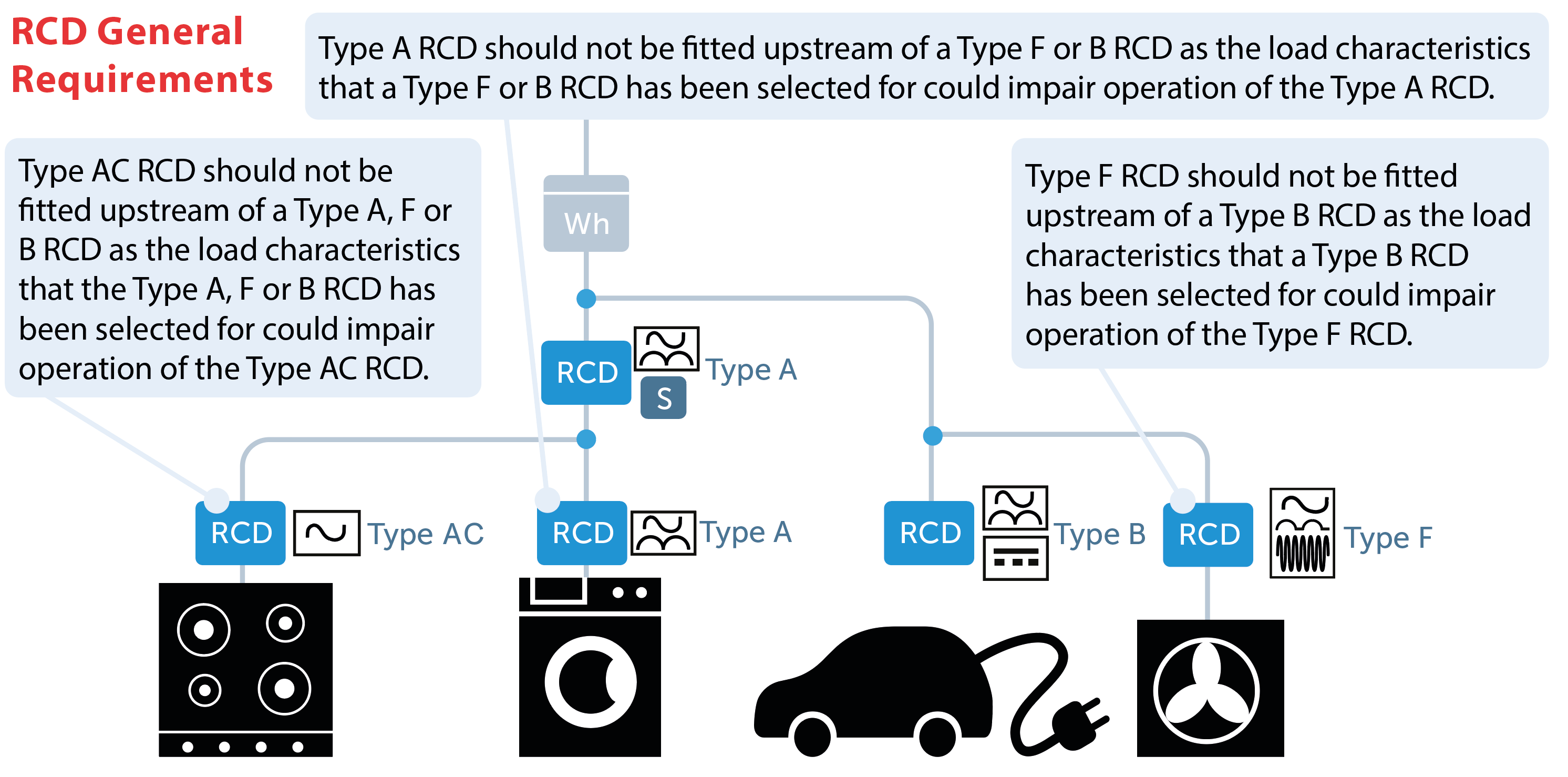

4. Residual Current Devices (RCDs)

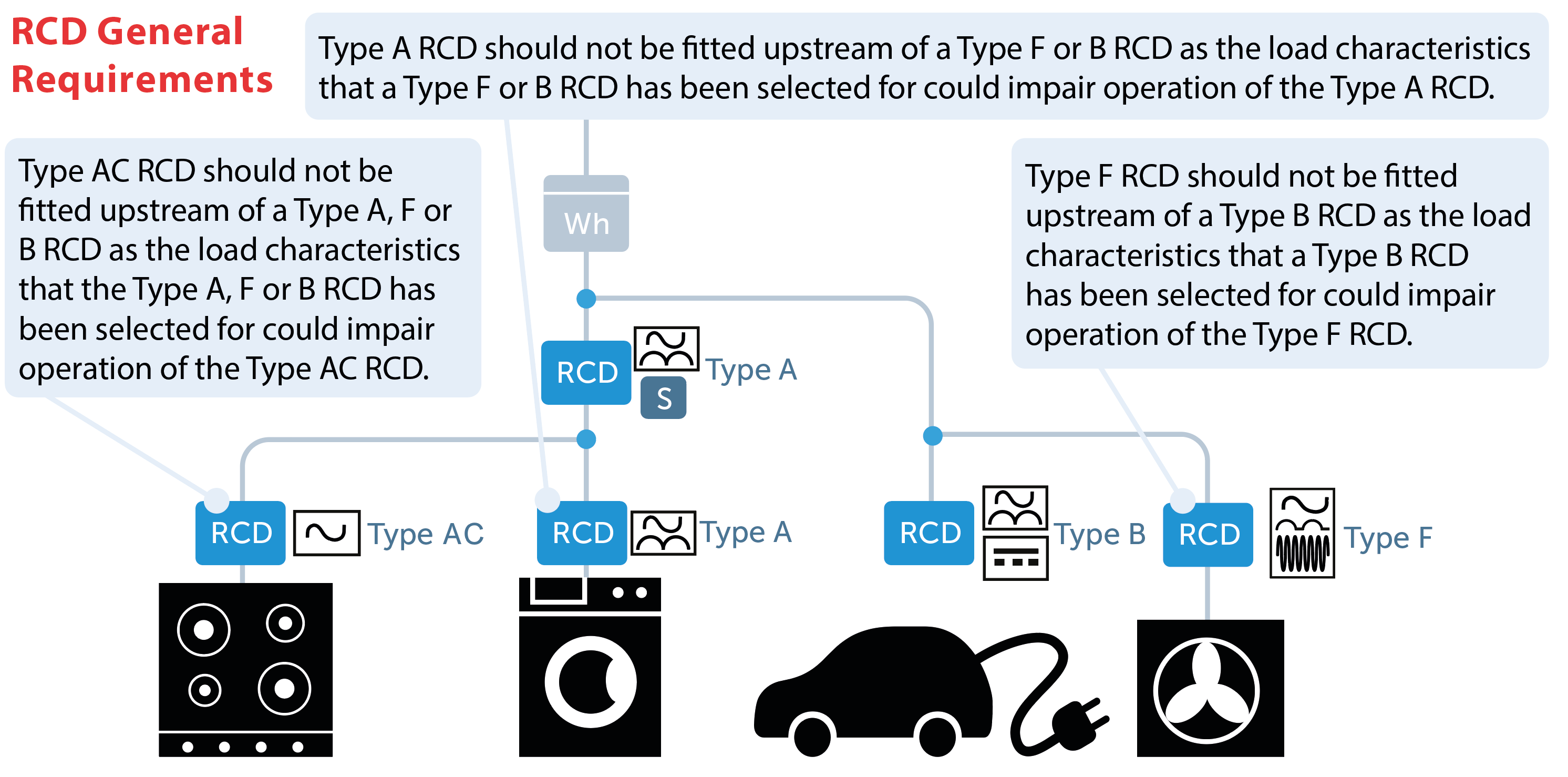

BS 7671 includes specific Regulations for RCD provision for EVCP installations to protect against DC leakage currents.

Three ways to comply with the Regulations are:

-

Install a chargepoint with built-in 6 mA DC detecting device used in conjunction with a Type A RCD fault current protection

-

Install a Type B RCD at the point of electrical distribution which will serve the chargepoint

-

Install a separate DC residual current monitoring device in the supply to the chargepoint

A label/notice to indicate that the RCD push-button test should be conducted every 6 months to check that it switches off the supply is required as per Regulation 514.12.2.

This installation, or part of it, is protected by a device which automatically switches off the supply if an earth fault develops. Test 6 monthly by pressing the button marked ‘T’ or ‘Test’. The device should switch off the supply and should then be switched on to restore the supply. If the device does not switch off the supply when the button is pressed, seek expert advice.

RCD Test Label example

Fig 2. Example of RCD type selectivity

5. Cable Design

Cables used must be suitable for the environment in which they are installed. Any hole used or made to pass a cable through a wall must be sealed properly to maintain the integrity of the building structure.

EVCP supply cables

There are 4 common supply cable types that can be used:

-

Flat twin & earth

-

Steel-Wire Armoured (SWA)

-

A dedicated cable type for EV chargepoints with built-in communications

-

NYY (Poly-Vinyl Chloride (PVC/PVC) insulated cable)

Areas to be mindful of when installing supply cables are:

External cables to EVCP

BS 7671 requires a greater amount of mechanical protection be placed on external cable due to risks from degradation of the insulation and exposure to UV lights.

There are 5 main cable types used externally:

-

NYY (Poly-Vinyl Chloride (PVC/PVC) insulated cable)

-

Steel-Wire Armoured (SWA)

-

Flat twin & earth

-

A dedicated cable type for EV chargepoints with or without built-in communications

-

Singles (PVC insulated single-core cable conduit/trunking)

Areas to be mindful of when installing external cables are:

-

Water ingress

-

Lack of / incorrect or improper use of glands and shrouds

-

Proximity to services

-

Too tight bend radii

-

Poor choice of cable routing

-

Insecure / incorrect cable fixings

6. Certification and Notification Requirements

Electric Vehicle Chargepoint Installations are subject to a number of certification and notification requirements. These must be completed and issued to the customer to meet OZEV and DNO requirements and to comply with the Building Regulations.

Electrical Installation Certificate

On completion of the installation of an EVCP, an Electrical Installation Certificate (EIC) is required to be completed, signed and issued to the person ordering the work by the EVCP installer as per Chapter 64 of BS 7671.

Building Regulations Compliance Certificate

The addition of a new electrical circuit for the domestic EVCP must be notified to Local Authority Building Control (England and Wales only), and the person ordering the works must be issued with a Building Regulations Compliance Certificate.

Alerting the DNO

EVCP installers must assess each installation to determine whether an application to connect to the grid should be made to the DNO, or whether the connection can be made and the DNO notified after the event. For more information click here.

7. Main Protective Bonding

BS 7671 includes requirements for the main protective bonding for extraneous-conductive-parts. This is to prevent a dangerous electric shock in the event of an earth fault.

In each EVCP installation, checks must be made on the main protective bonding conductors that they are installed and correctly connected to the main earthing terminal extraneous-conductive-parts including the following:

-

Water installation pipes

-

Gas installation pipes

-

Other installation pipework and ducting

-

Central heating and air conditioning systems

-

Exposed metallic structural parts of the building

8. Correct labelling

The EVCP circuit must be clearly labelled to allow for easy identification.

This is very simple to do but is often missed out, resulting in improvement actions being recorded.

9. Height of Socket-Outlet and Display Screen

Requirements for the height at which the EVCP socket-outlet and display screen are installed are set out to avoid damage from vehicle bumpers and to ensure their accessibility in accordance with the IET Code of Practice for Electric Vehicle Charging Equipment Installation.

-

The socket-outlet must be installed between 0.75 m and 1.2 m off the ground

-

The display screens should be installed between 1.2 m and 1.4 m above ground, viewable by a person standing or sitting

10. Consumer Units

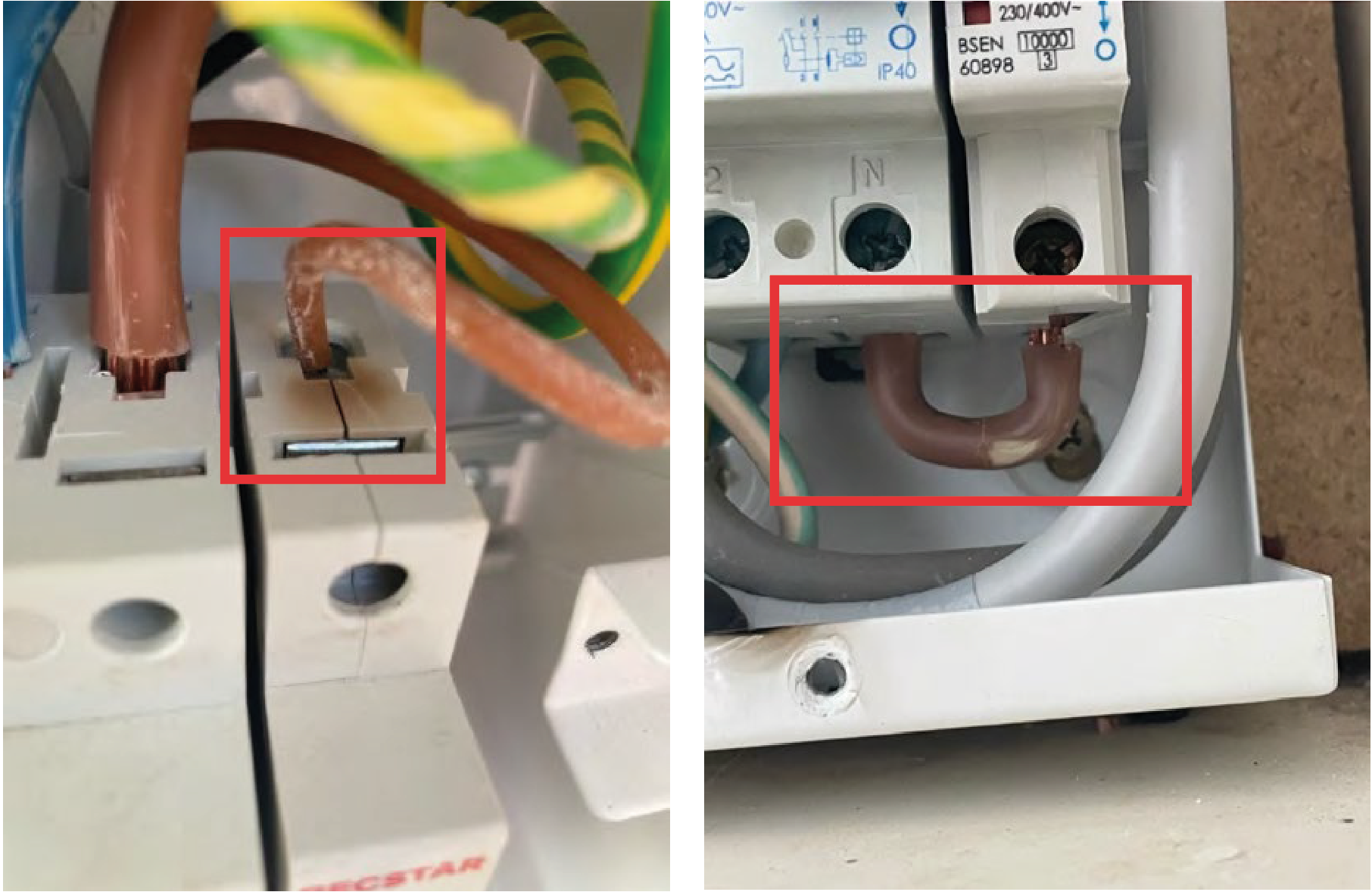

Be aware of common issues found on new or existing consumer unit’s where EVCP’s have been installed:

As the EVCP installation must be in full compliance with BS 7671, any part of the existing installation that can have a material effect on the EVCP shall be considered for correction.

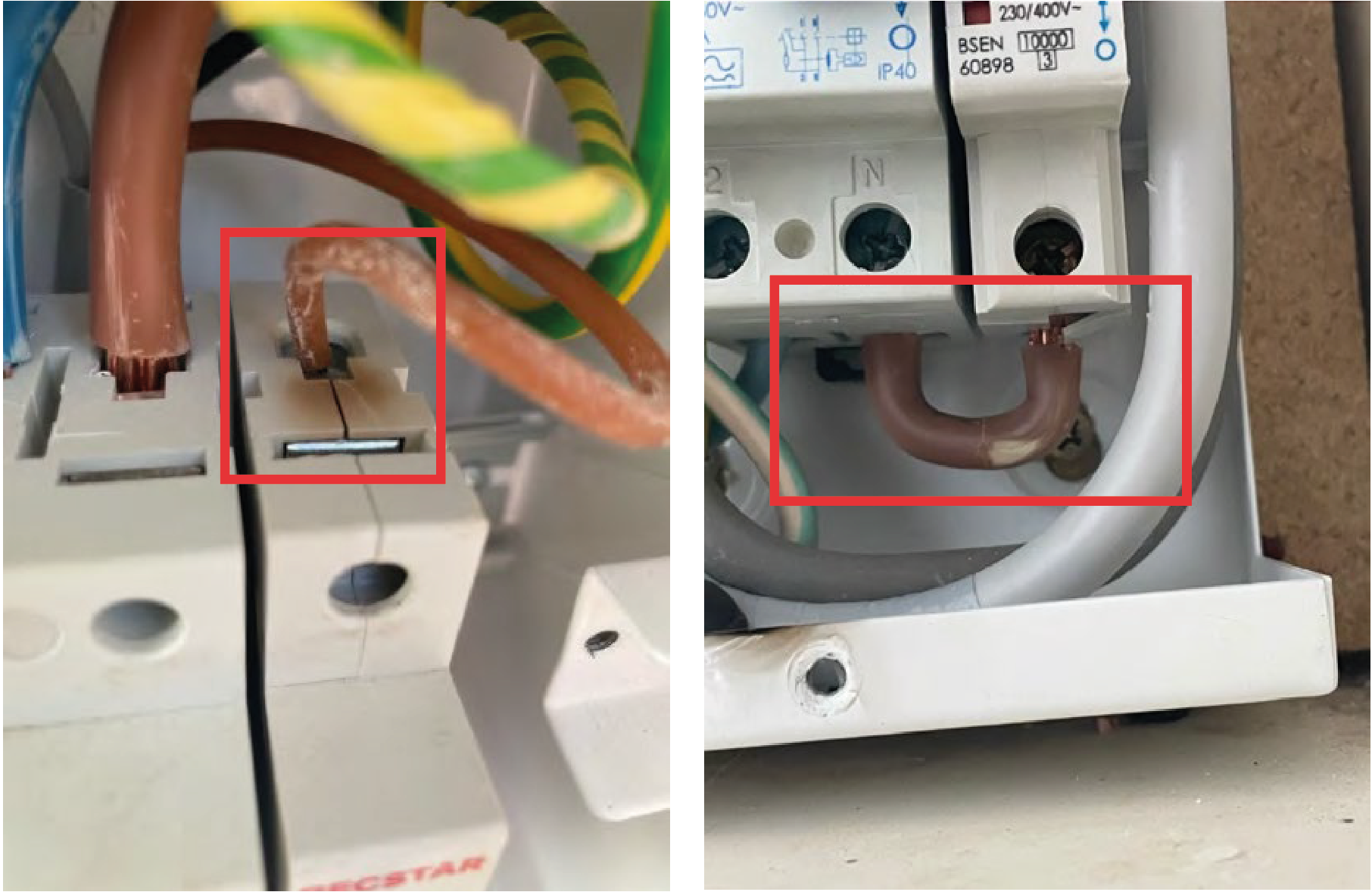

Therefore, extra care and consideration should be given to all of these areas when completing an EVCP installation, examples are shown in Fig 3.

Fig 3. Examples of heat and connection damage.

The content for this article has been provided by NAPIT and is available to download as a PDF datasheet.